- Your cart is empty

- Continue Shopping

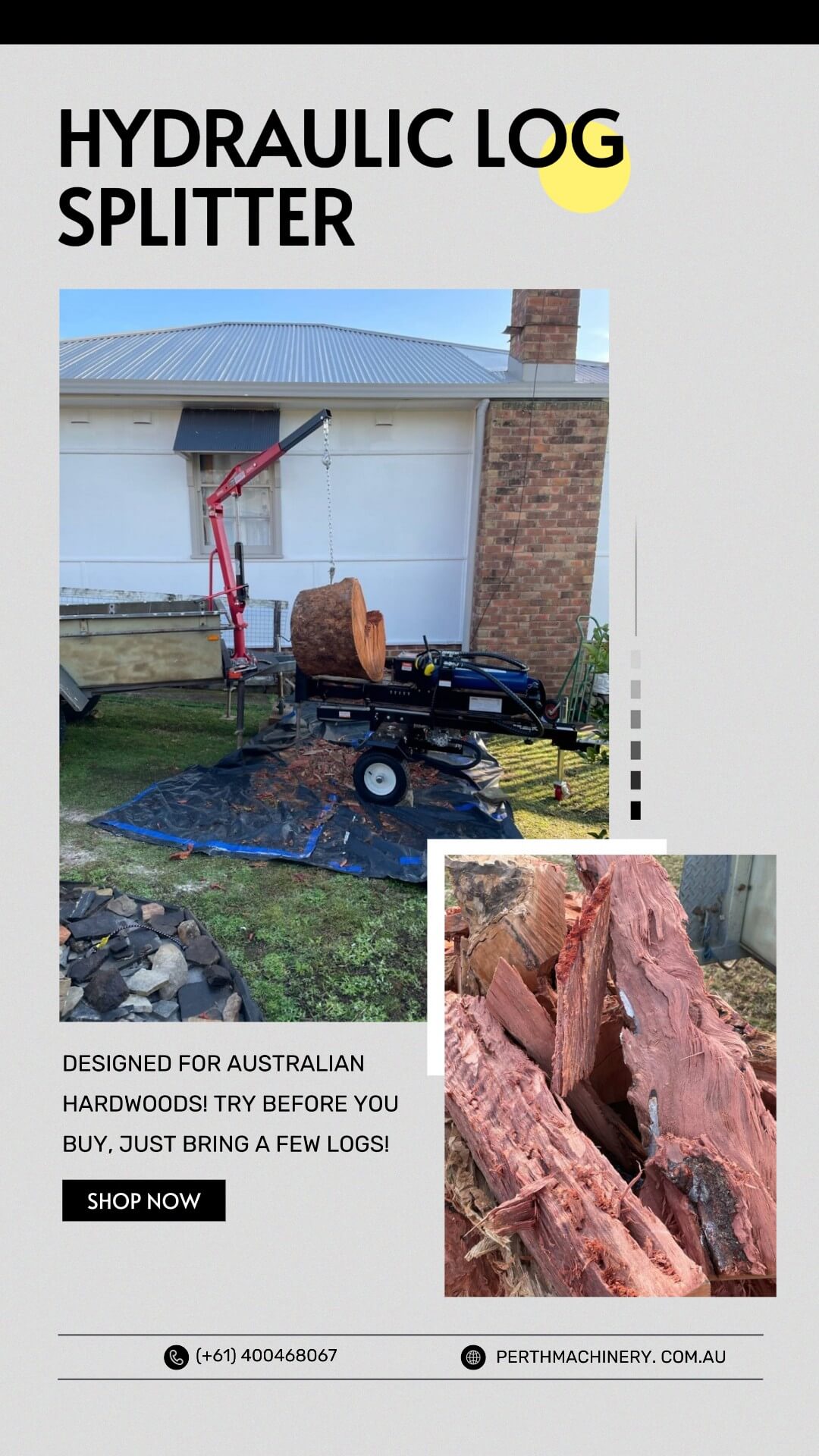

50 Ton Hydraulic Log Splitter

$2,650.00 – $2,850.00

Product successfully added to the Quote List

Product Description

More Information for 50 Ton Hydraulic Log Splitter:

- Hydraulic Log Splitter designed for Australian Hard Wood, Western Australia has some of the hardest wood in the world for splitting.

50 Ton Hydraulic Log Splitter (amazing value).. - We have many years of Log splitter knowledge. You do not need to look any further as this model will split your logs with ease. We hold all major spare part components with these log splitters and are compatible with other models.

- Crate size 2255mm length, 550mm width, 500mm height and weight 381kg.

New 2020 Model 40 Ton Log splitter.

Designed for Australian Hardwoods.

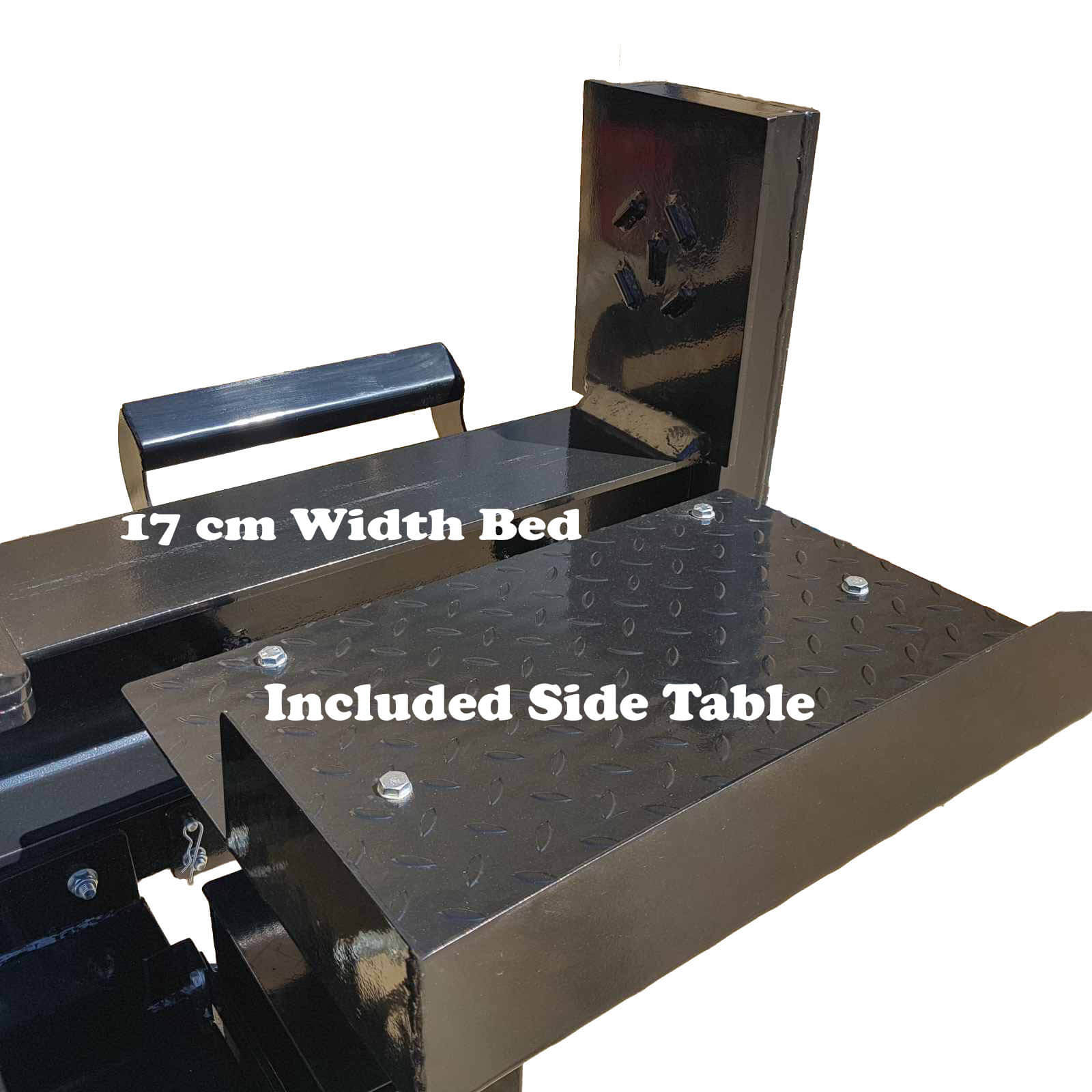

Improvements Are - Special Inc Jockey Wheel and Side table.

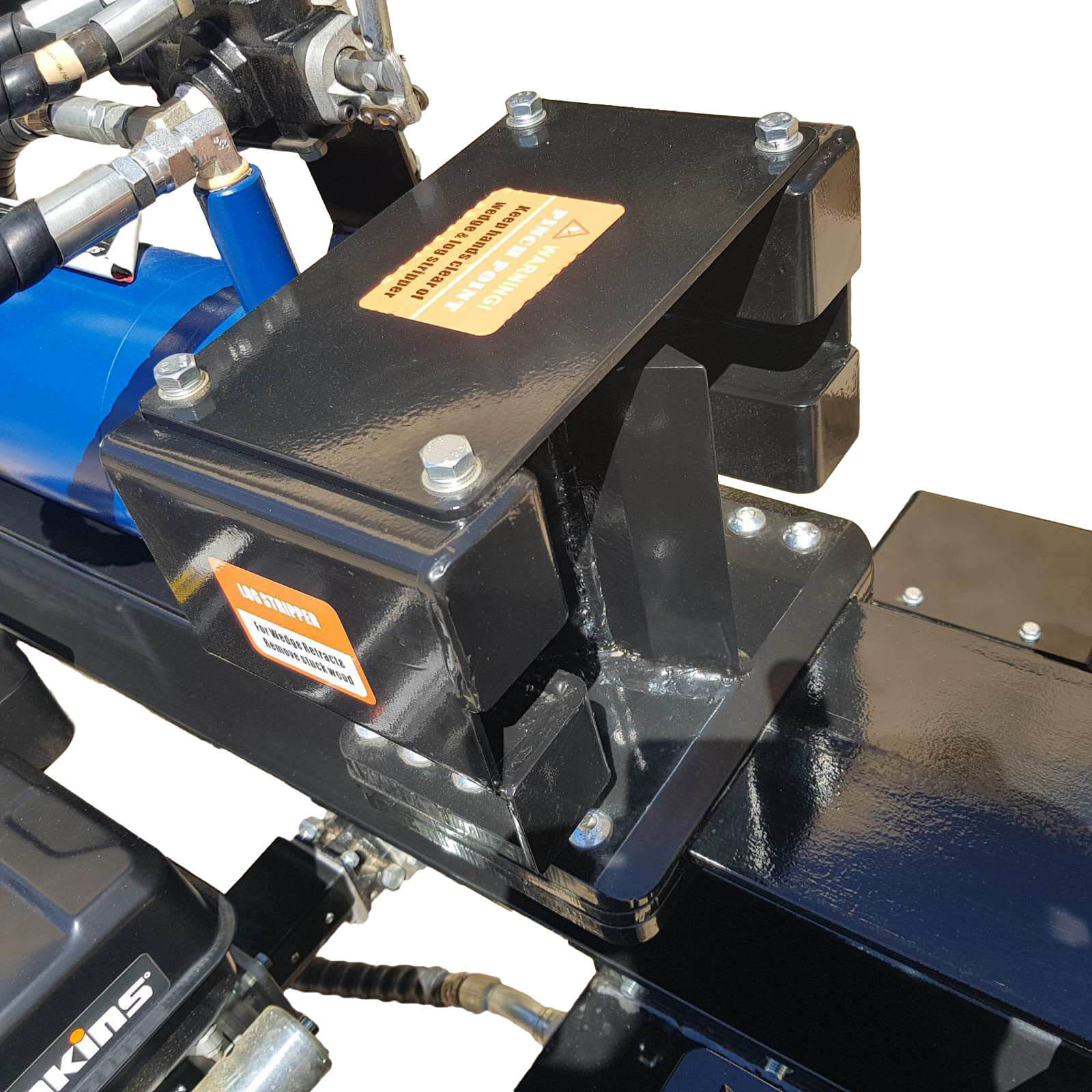

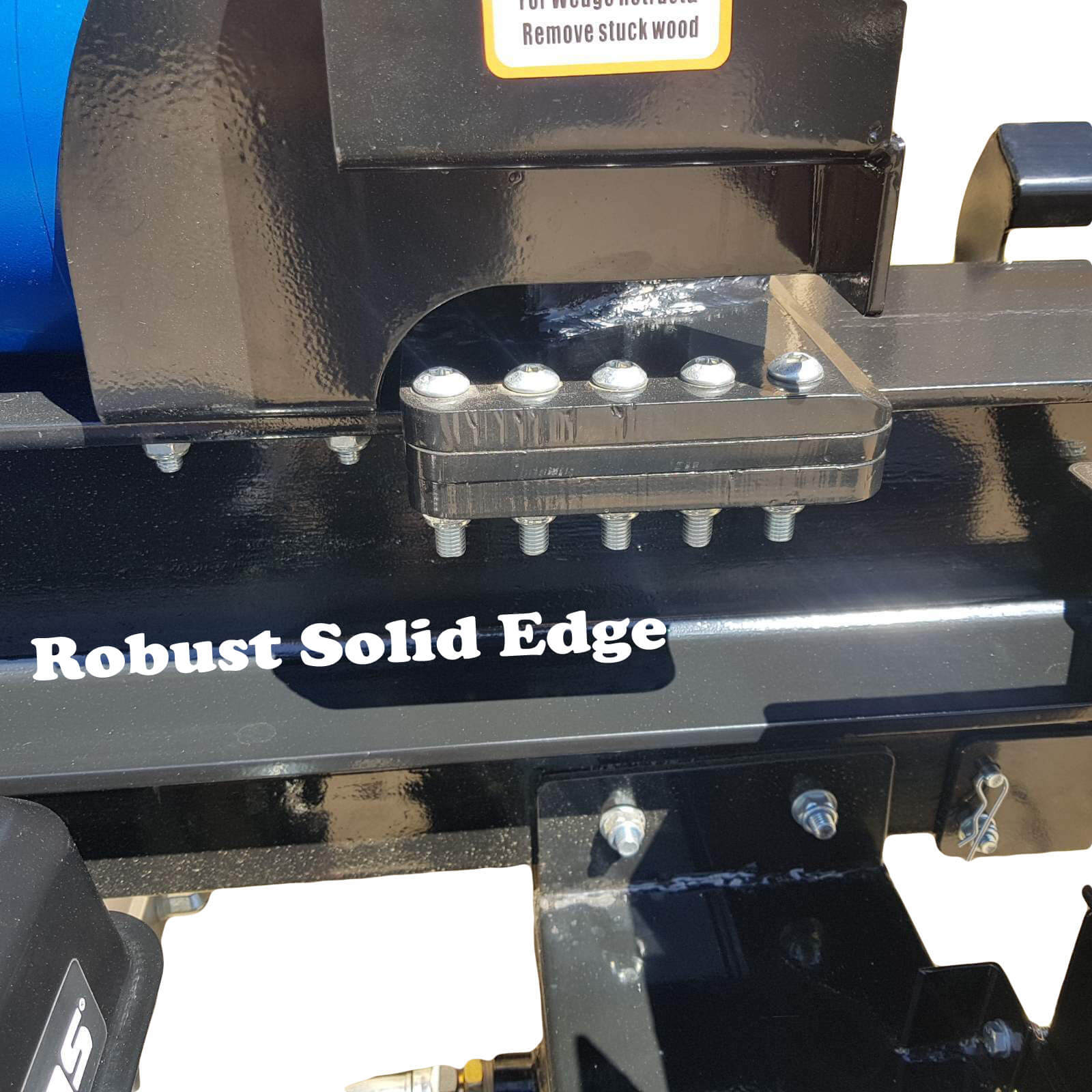

- With Unique WEDGE and BASE Plate like no others on the market..

- Hydraulic Cylinder Shaft Rod size 60 mm diameter

- Wedge base plate increased from 12 mm to 16 mm steel plate

- Improvements keep to continue and the improvements are passed on at cost to keep the price lowest as possible.

- Foot re-design with reinforced plate criss cross welded inside as old design of solid plate type bends.

- Large foot to hold log now 500mm, standard type 300mm

- Bigger criss cross on foot to hold log in position

- Hydraulic Breather cap change from Plastic to metal

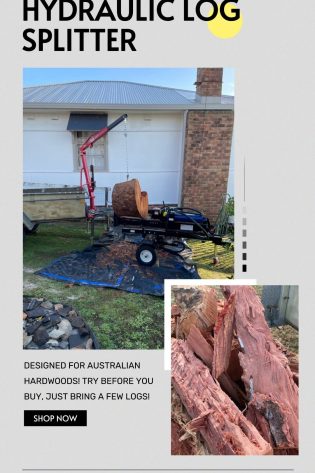

- Cutting Wedge Blade not cast iron type, redesign specially for the Australian Hard Wood which can bend.

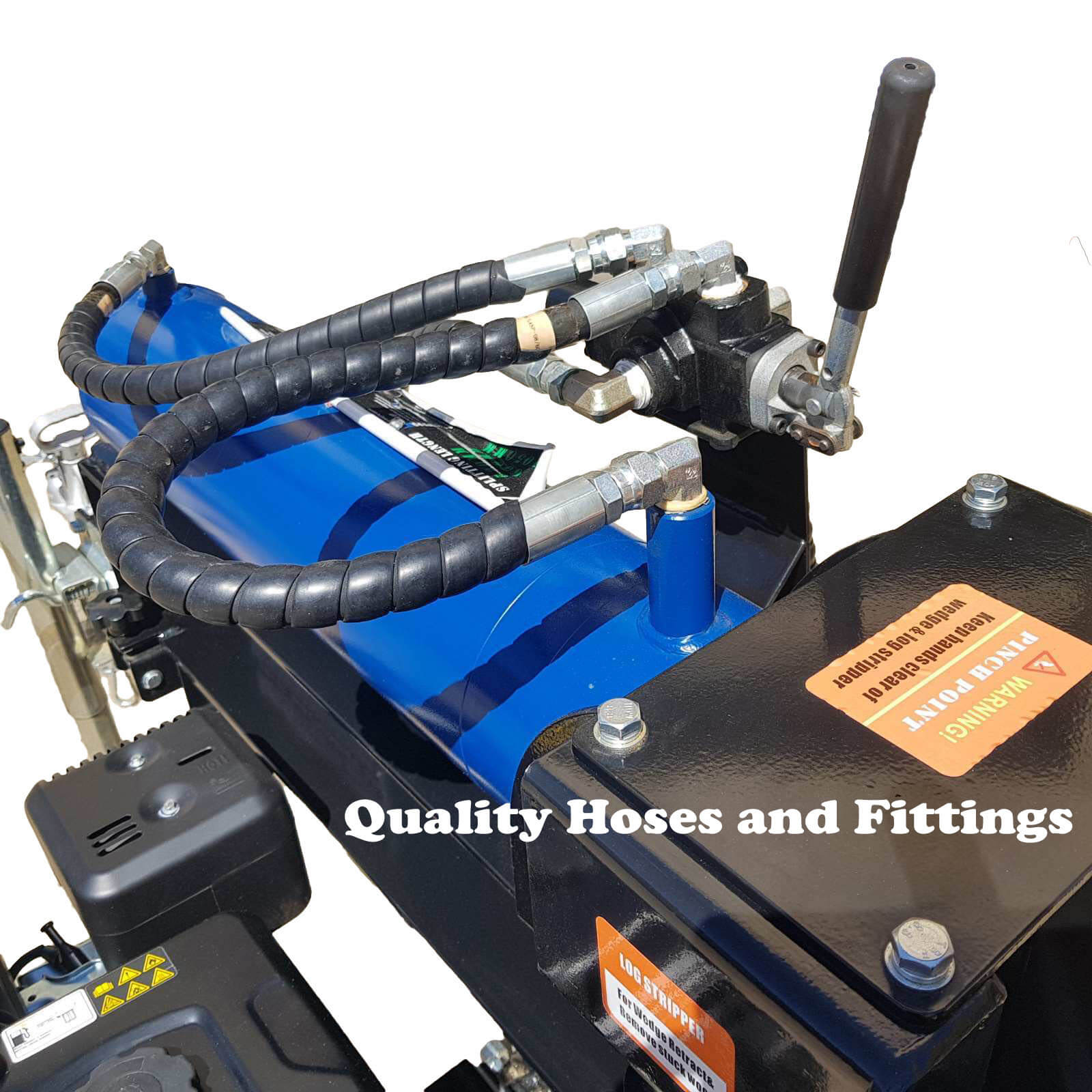

- Control Valve shifted from top of hydraulic cylinder to side to stop movement ( previous causes oil leaks)

- The 50 Ton Hydraulic log splitter. We now have upgraded the 50 ton to a Genkin E-Start 456cc/18hp engine and 5.5” cylinder with a single hand controlling valve.

New improvements have been for 50 Ton Hydraulic Log Splitter made to all splitters.

Choosing the right Log Splitter

Most people focus on the engine, hydraulic pump pressure and the cycle time. Really that’s the wrong parts to focus on. The Wedge, Foot and hydraulic cylinder are the biggest weakness of a log splitter.

The Engines and 2 stage hydraulic pumps are sized to cut Western Australian wood. A pump with a pressure greater than 3200 psi and 16 GPM flow will have no issues. Hiring log splitters allowed us to test the log splitter to every extreme as we know people who hire don’t take the same care if you own. From this information we are able to build the best log splitter knowing the problems you never even considered

Thoughts to Consider When Choosing

When choosing a log splitter there are important parts that you need to consider.

The foot, if not constructed well the steel could bend or welds could crack from the huge force been applied.

The wedge is it strong enough not to bend to split Western Australian hard wood? As WAs wood has twists, knotty, the wood puts huge pressure on the steel.

Construction of the hydraulic cylinder and the hydraulic seals can they handle the heat? The domestic log splitters do not have an oil cooler so the oil can get hot. We recommend around 85 degrees and that’s why our log splitters have a temperature gauge on the tank so you can determine when to shut the machine down to let the oil cool.

When the hydraulic cylinder get excessively too hot the hydraulic cylinder heats up and expands the metal. The force can loosen the front screw cap and with time can cause a weep of hydraulic oil. Oil too hot can also degrade the seals. We are happy to show you the seals that we use in our hydraulic cylinder.

Additional Information

| Option | Crate No Oils, Assembled With Oils |

|---|

Reviews

There are no reviews yet.